The main test instrument for transformer oil is automatic closed flash point tester.

The main component of the instrument is a metal oil cup, the inner wall of the cup has a certain amount of calibration loop, installed in the bottom of the heating chamber for the electric furnace plate, furnace wire current is controlled by the switch box.

The lid is made of a double-layer metal plate with holes, and the top can rotate automatically.

When heating, the holes of the two cover plates are staggered, so that the oil cup is in the closed state. When ignition, the upper cover plate rotates, the holes of the two cover plates coincide, the igniter automatically probes into the orifice to ignite the mixed gas, and the temperature shown in the thermometer is the flash point.

Transformer oil flash point detection can use SH105B closed flash point automatic tester, SH105B automatic closed flash point tester is the use of microcomputer technology, large screen LCD LCD display.

Instrument according to the standard method of heating, automatic rise and fall, automatic ventilation, automatic ignition, automatic display, automatic locking flash point value, automatic printing results.

After the test can be automatically cooled, to achieve the full automation of the work process.

It has the advantages of accurate measurement, good repeatability, stable performance and simple operation.

Widely used in electric power, petroleum, chemical, commodity inspection, scientific research and other departments.

In accordance with ISO - 2719,ASTM D93, GB261-2008 standards

Instruments for the experiment

1.SH105B Automatic Closed Flashpoint Instrument, developed and produced by Shandong Shengtai Instrument Co., Ltd.

2. Closed flash point special cup

Experimental steps:

First, preparation work

1. After the instrument is unpacked, please count the accessories according to the packing list. If there is any damage, please contact our company.

2. The instrument should be carried vertically, and the tilt Angle along the height of the instrument should not exceed 30 degrees. It should be placed in a dark place and placed smoothly, otherwise there will be vibration after the start of the instrument, which will affect the service life of the instrument.

3, the instrument power supply is connected to the capacity of more than 220V/10A socket, pay attention to must have a good grounding wire.

Second, the experimental process

1. After the power is switched on, the test arm of the instrument is automatically lifted to display the experimental interface.

Click "Start", and the test arm falls down to start the test;

Click "Stop" to stop the test and lift the test arm.

The "Test Conditions" section shows the test setting conditions, including the expected flash point, printer switch Settings, and the standard applicable to the test.

The "Test Information" section displays the test progress information.

In the test interface, click "Self-test", "Settings", "Conditions", "Record" and other buttons to enter the corresponding functional interface.

2. Self-check interface

Under this interface, self-check operation can be performed on each component of the instrument.

Click "Test Arm", the test arm component rises;

Click again and the test arm assembly falls.

Click "igniter", point the bright firearm;

Click again to extinguish the igniter.

Click "Stir" to start stirring.

Click again to turn off mixing.

Click "Open the lid" to start the sliding plate of the cup lid and automatically return to its position.

Click "Printer" to start the printer to print self-test. The printer will print the simulated test results (not the real test results) to verify whether the printer works normally.

During the self-test of each component, the corresponding operation information will be displayed below it.

3. Set the interface

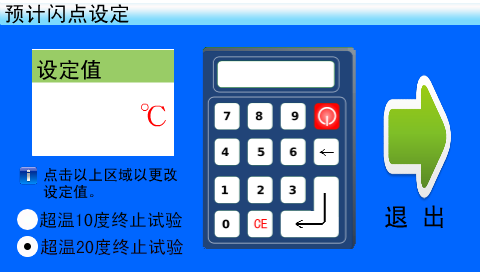

Under this interface, you can set the estimated flash point value and atmospheric pressure value. Click "Change" after "Estimated Flash Point" or "Atmospheric Pressure" to enter the interface for setting the estimated flash point or air pressure:

Expected flash point setting