Automatic solution for four - ball test with extreme pressure of lithium - based lipids

All grease has pressure resistance, and the extreme pressure additive grease, the general extreme pressure performance is better, can not say that the grease has extreme pressure performance.

Indicator, generally look at the extreme pressure PB value, the greater the value, the higher the load resistance capacity, that is, the better the extreme pressure performance, according to GB/ T7333-2008 <

Extreme pressure lithium lubricant ester >

Requires, according to the four-ball method to detect PB value, the standard requirement is not less than 588N.

Methods the profile

Three steel balls with a diameter of 12.7mm are clamped in an oil box and covered by the test oil. Another steel ball of the same diameter is placed on top of the three balls and subjected to 147N(Qiaohe) or 392N(40kgf) force, which becomes the "three-point contact".

When the oil test reaches a certain temperature (75℃ ± 20C) and the head ball rotates at a certain speed for 60min, the anti-wear performance of the oil test is evaluated by the average of the spot diameters of the following three balls.

The extreme pressure performance test of SH120 automatic four-ball machine grease is in the form of sliding friction and is mainly used to evaluate the bearing capacity of lubricants under the condition of extremely high point contact pressure.

In practical application, different evaluation indexes can be selected according to different uses of lubricants.

The four-ball friction testing machine can also do lubricant long-term wear resistance test, determination of friction coefficient, record friction and temperature curves.

Equipped with special spot measurement system, can realize the calculation screen display, measurement and record of the friction pair spot.

Special accessories can also be used for the end face

Friction and material simulation test.

Based on the loading stability of the lever four-ball machine and the loading characteristics of the servo valve, the servo motor, air spring and closed-loop control software are used to realize automatic zero clearance and automatic control

Dynamic loading, automatic holding, automatic test, automatic unloading, automatic measurement of spot diameter and photo taking, one key operation

For data storage, a key to save the test speed, minimal error, good repeatability, no pollution, no noise, high efficiency.

GB/ T12533-98, Lubricant extreme pressure performance determination method (four ball machine method);

GB3142-82, Lubricant bearing capacity determination method (four ball method);

SH/T0189-92, Lubricating oil wear resistance determination method (four ball machine method);

SH/T0202-92, Grease extreme pressure performance determination method (four ball machine method);

SH/T0204-92, Determination of wear resistance of grease (four-ball machine method).

Zbe34007-87 (wear resistance test method with four spheres)

Instruments for the experiment

1.SH120 Automatic Four Ball Machine, Shandong Shengtai Instrument Co., Ltd.

2. Special spot measurement system.

The working conditions

A. Room temperature in the range of 10~35℃;

B. Relative humidity shall not be greater than 80%;

C. In the environment without vibration, corrosive media and strong electromagnetic field interference;

D. The fluctuation range of supply voltage shall not exceed ±10% of the rated voltage, the fluctuation range of frequency shall not exceed 2% of the rated frequency, and the unbalance voltage of three-phase voltage shall not exceed 10V;

E. Proper installation on a solid foundation, with a level of no more than 0.2/1000.

Usage and operation

Test operation panel part

The right side of the test operation panel is the test parameter control and display part.

The caution section panel is shown in Figure 2.

The test operation

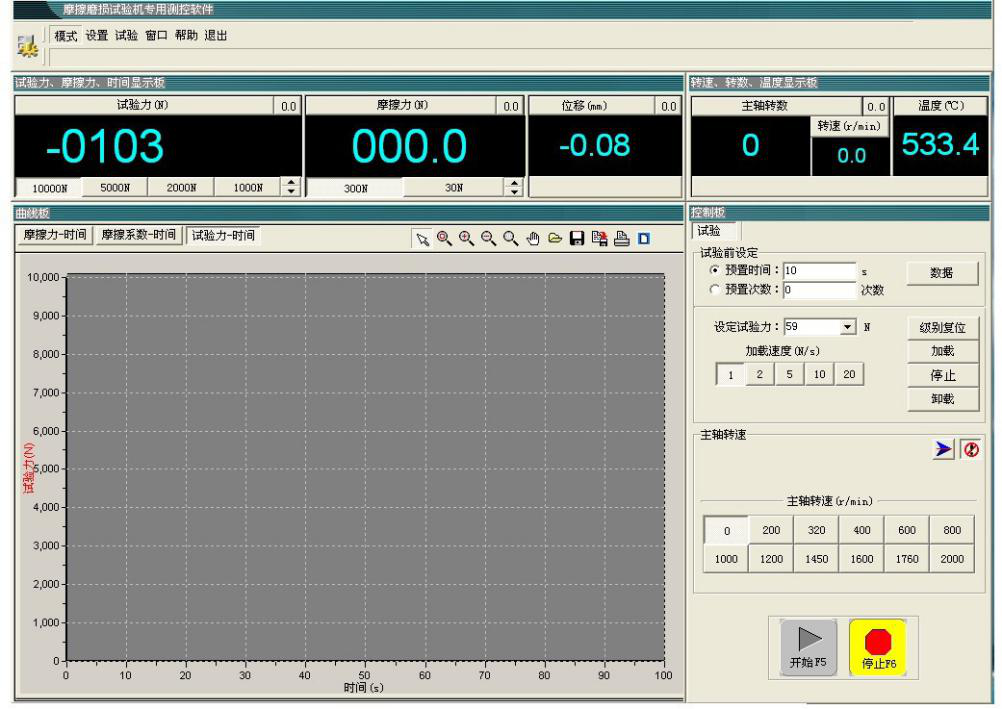

The panel diagram is shown in Figure 2 and 3. First, the power of the testing machine should be connected, and the computer switch button should be turned on to enter the display interface. Then, the test operating software should be opened to enter the operating interface of the testing machine.

Figure (4)

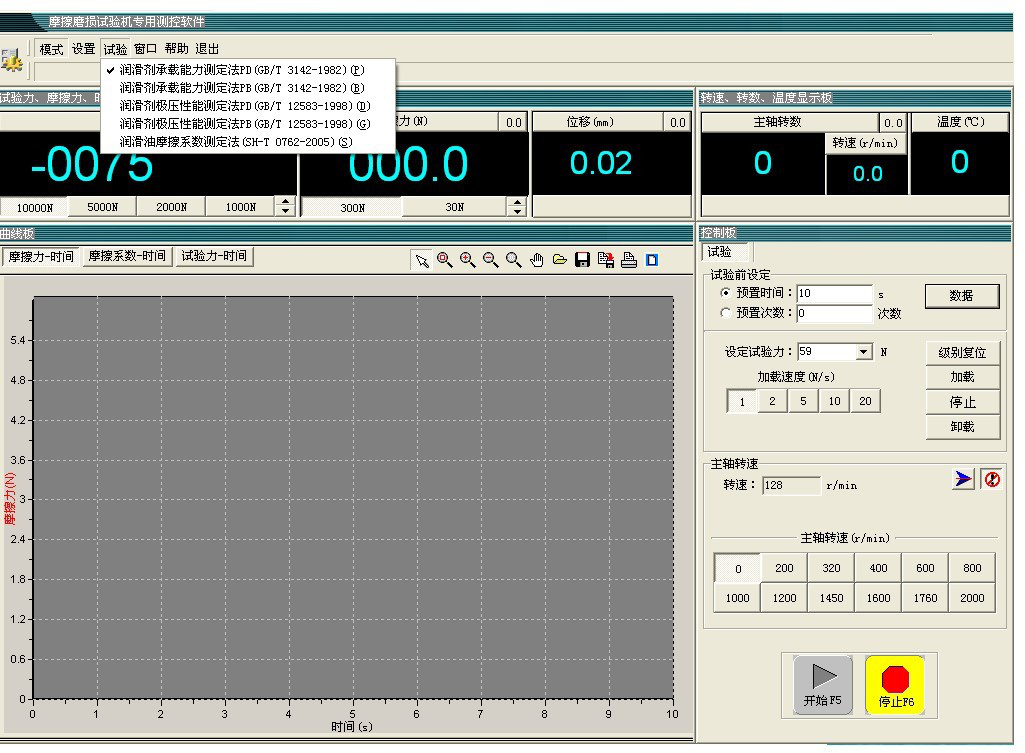

Test selection, as shown in Figure (5)

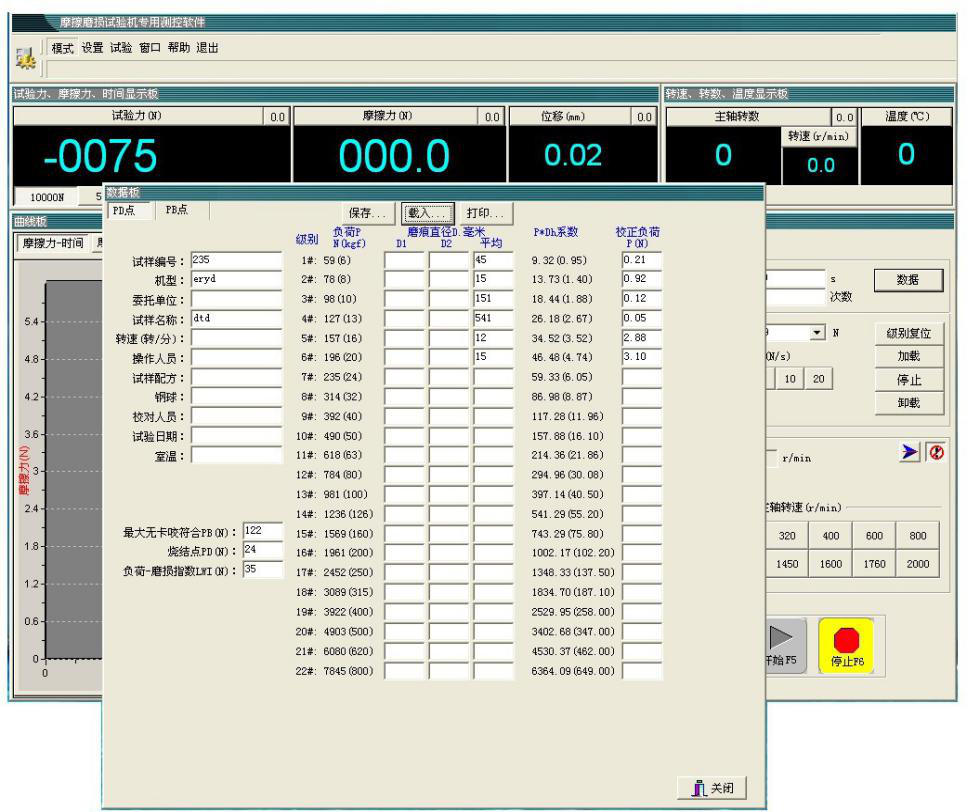

The test data board is shown in Figure 6

Before the test, first install the sample, ready to open the motor spindle preheat for 15 minutes, click the "Quick Rise" button, the piston rises, the piston rises in the process, the test force, friction, time, period for zero, and on

Each parameter is preset, press the speed selection button to select the speed, press the button to start the test, the main engine automatically stops the test when the set time is reached.

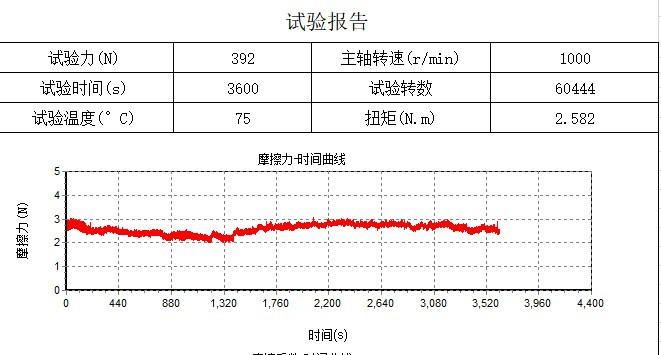

Report of Experimental Results (Report of Friction)