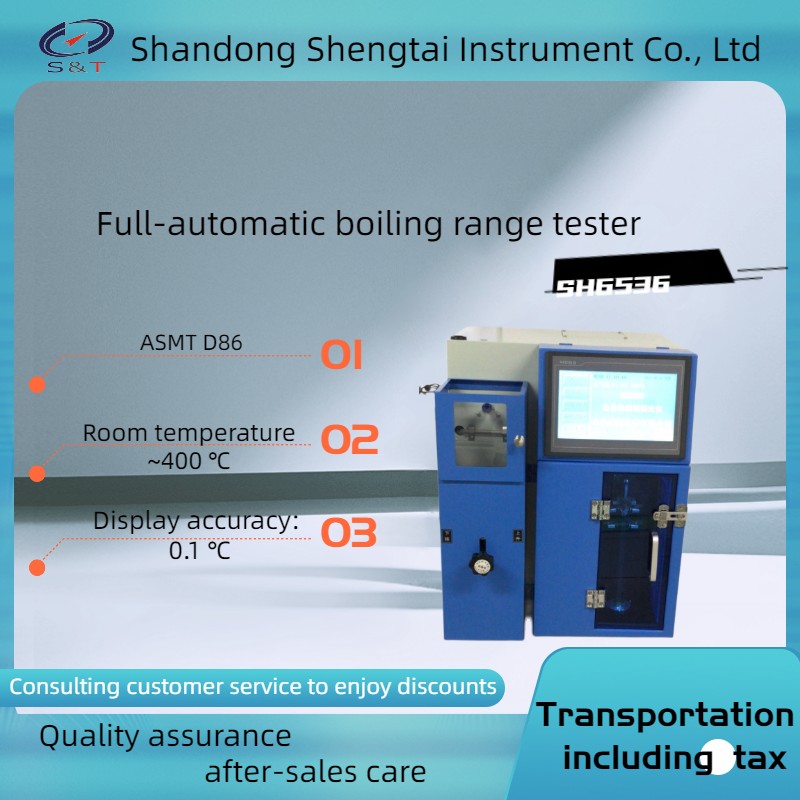

SH6536 Automatic distillation boiling range tester adopts color liquid crystal display screen, Chinese menu man-machine dialogue, guide operation, the determination process is fully automated.

According to the national standard GB/T6536 distillation of petroleum products determination method and GB/T6536, the ASMT D86 standard GB/T7534-2004 industrial volatile organic liquid boiling range determination of distillation range determination of methanol and alcohol products standard method to design and manufacture, apply to under atmospheric pressure boiling point, and stable chemical performance in the process of distillation of organic liquid (such as hydrocarbons, esters, alcohols, ketones, ethers, and similar organic compounds).

Standard:ASTM D86 ASTM D850 ASTM D107

At the same time, it is suitable for the determination of distillation range of petroleum products, industrial volatile organic liquids and organic solvents for raw materials.

Adopts embedded computer, imported IPC, 12.1 inch large LCD touch screen, friendly man-machine dialogue interface, convenient test and operation.

Using single chip microcomputer and intelligent control technology, the heating and cooling of distillation test process, distillate liquid level tracking, distillation rate control, recovery liquid volume control, temperature recording, test results printing, etc., are all automatically completed.

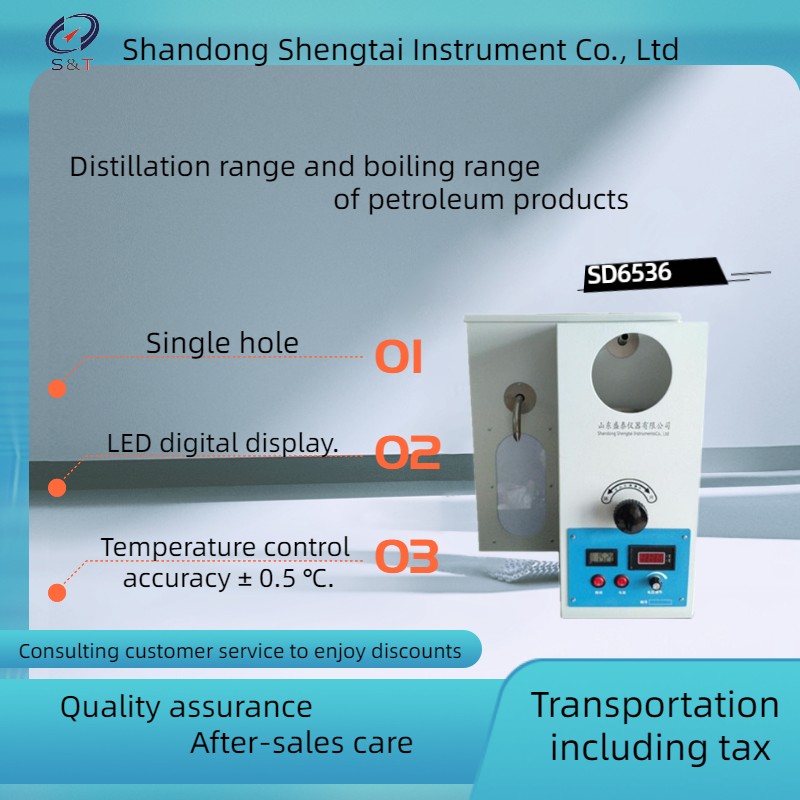

Boiling Range of Organic Liquid Tester boiling spread equipment distillation range analyzer

Automatic petroleum product distillation tester ASTM D86 ASTM D850

|

1, Power |

AC220V±10% 50Hz |

|

2, Heating power |

2KW |

|

3, Cooling power |

0.5KW |

|

4,Indoor working environment |

temperature: 10-38°C (recommend: 10-28℃); humidity≤70%. |

|

5, Steam temperature |

0-400℃ |

|

7, Refrigeration temperature |

0-60℃ |

|

8, Refrigeration accuracy |

±1℃

|

|

9, Temperature measurement accuracy |

±0.1℃ |

|

10, Volume accuracy |

±0.1ml |

|

11, Fire alarm |

extinguish by nitrogen (prepared by customer) |

|

12, Sample state |

suitable for natural

gasoline (stable light hydrocarbon), motor gasoline, aviation gasoline, jet

fuel, special boiling point |

Main Performance Characteristics

Second, functional characteristics

● The instrument by the industrial computer automatic measurement and control test process, full touch 10.4 inch LCD display test,

● Display temperature and volume data and related curves throughout the process.

● The liquid level tracking system is composed of high subdivision step American linear motor and imported photoelectric tracker.

● Cold tube temperature, measuring cylinder chamber temperature, using mechanical refrigeration, compressor for foreign famous brand manufacturers.

Internal circulation of the cooling medium.

Cooling water can be added once every 3 years.

● Electric distillation furnace heating automatic control, so that the sample from the initial distillation point to 95% of the flow rate, control within 4 ~ 5ml per minute.

● Can provide the initial and final distillation point temperature value, can provide the temperature value of each percentage point and flow rate.

● Automatic detection of local atmospheric pressure, automatic correction to the standard atmospheric pressure temperature.

● You can choose to stop the test according to steam temperature or recovery volume.

● The instrument can store, query, print test results.

|

Temperature range |

room temperature ~ +400°C accuracy ±0.1°C |

|

Display accuracy |

0.1℃ steam temperature sensor: Germany import PT100 platinum resistance |

|

Start heating to the initial distillation point |

5 ~ 15 minutes |

|

Distillation rate |

2 ~ 10ml/min |

|

The temperature of the initial distilling point |

the optical fiber sensor |

Technical parameters

1. Temperature range: room temperature ~ +500°C accuracy ±0.1°C

2. Display accuracy: 0.1℃ steam temperature sensor: Germany import PT100 platinum resistance

3. Start heating to the initial distillation point: 5 ~ 15 minutes

Distillation rate (flow rate from initial distillation point to 95% recovery) : 2 ~ 10ml/min (adjustable)

5. The remaining amount of 5ml in the flask to the end point: no more than 5 minutes

6. The temperature of the initial distilling point is detected by the optical fiber sensor

7. Recovery volume measurement range: 0 ~ 100ml

8. Measuring accuracy of recovery volume: ± 0.1ml

9. Volume measurement: liquid level tracking system, mainly composed of stepper motor and optical fiber liquid level sensor, motor step 0.01ml each time

10. Cooling system: Compressor refrigeration

11 cold bath temperature: -5 ~ 60℃

12. Recovery chamber temperature: 0 ~ 40℃

13. The equipment has the function of automatic detection of local atmospheric pressure and automatic correction of temperature under standard atmospheric pressure

14. With fire extinguishing system, in case of fire, manual nitrogen extinguishing can be used to prevent the safety accident of heating distillation flask bursting (the nitrogen bottle needs to be provided by the customer)

15. Equipped with safe temperature setting function, the temperature range from room temperature to 400℃ can be set arbitrarily. If the heating temperature exceeds the set safe temperature, the instrument can automatically stop the experiment and blow heat dissipation immediately.

16. The instrument can automatically detect and display the temperature and flow time at every 5% volume point.

17. The instrument can automatically detect the temperature and occurrence time of the initial distillation point and the final distillation point.

18 can choose a variety of automatic stop mode, such as the final distillation point automatic stop, set to the specified temperature to stop, set to the specified volume to stop.

Packing list

S/N

Name

Num

Unit

remarks

1

Host

1

set

2

Sensor

1

piece

3

Distilling flask

2

piece

125ml

4

Measuring cylinder

2

piece

100ml

5

Heating support plate

2

set

6

deflector

2

set

7

Zeolite

1

set

8

Power cord

1

piece

9

Fuse tube

1

piece

10A

10

Instruction manual

1

Copy

11

Packing list

1

copy

12

Certificate of qualification

1

copy

Company

Introduction

Shandong Shengtai Instruments Co., Ltd. is

specialized in the research and production of experimental testing instruments

and industrial testing instruments. It is a professional instrument company

integrating instrument research and development, manufacturing, sales and service.

Its products are widely used in food, flour, grain and oil, Feed, electricity,

petrochemical, industrial oil, aerospace, coal quality and other industries.

For more than 10 years, Shengtai has always

been adhering to the "first-class service, customer first" as the

purpose, "reasonable price, honesty and trustworthiness" as the

business policy. Adhere to technical innovation, with rich knowledge of the

technical team and experienced, thoughtful after-sales service team.

Shengtai instrument as one of the most

large-scale and competitive enterprises in the industry, with the strength of

technology research and development, professional technical knowledge and

innovative design concept, in the model improvement, Significant technical

breakthrough has been achieved in the development of function expansion and

intelligent control system.

OUR

service

After-sales service commitment, our company

to sell the product after-sales service commitment: warranty period of one

year, long-term technical support outside the warranty period. During the

warranty period, the seller shall bear the cost of the replacement of the

equipment, the freight and maintenance of the instrument; outside the warranty

period, the seller shall waive the maintenance fee and charge only the cost of

the basic materials and freight charges when the instrument is malfunctioning

and the seller shall not charge the maintenance fee during the warranty period.